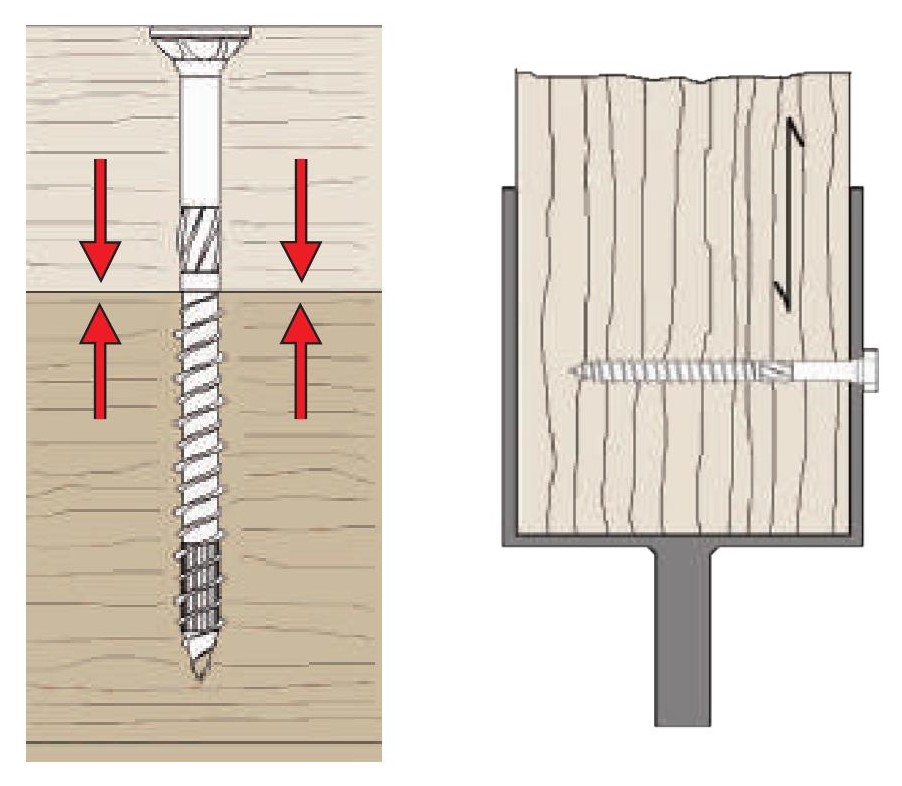

1 | Head geometry

Underhead milling mockets for optimal countersink:

- Smooth

- Gentle on material

- Also ideal for fittings

2 | Straight friction part

The new optimized friction section considerably reduces screw resistance:

- Less force required when screwing in

- Fast screwing

- Improved battery life of the drill/driver unit

3 | Thread

Single thread:

- Minimized blast effect

- Improved pull-out values

- Quicker screwing

4 | Tip

New improved patented compression tip:

- Improved bite in of the screw

- Lower splitting effect

Available sizes

RAPID® Hardwood are available in 8 x 120 to 8 x 240 mm.

MORE

Additional information

| Head Geometry | Counter Sunk |

|---|---|

| Shank Geometry | Friction Part |

| Thread Geometry | Partially Threaded |

| Tip Geometry | Compactor Tip |

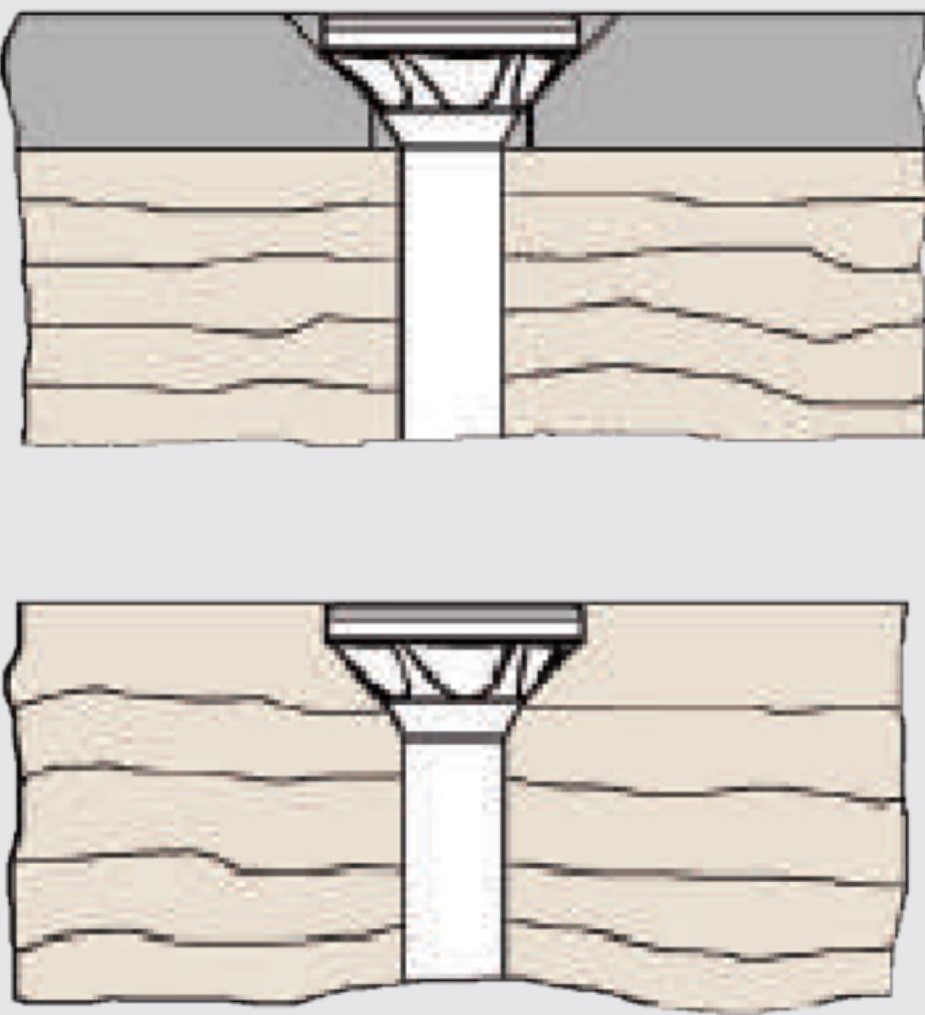

Counter Sunk

Countersunk heads are counter-sinkable in wood or even in prepared steel plates. The milling pockets reduce the fraying and splintering of the wood.

Friction Part

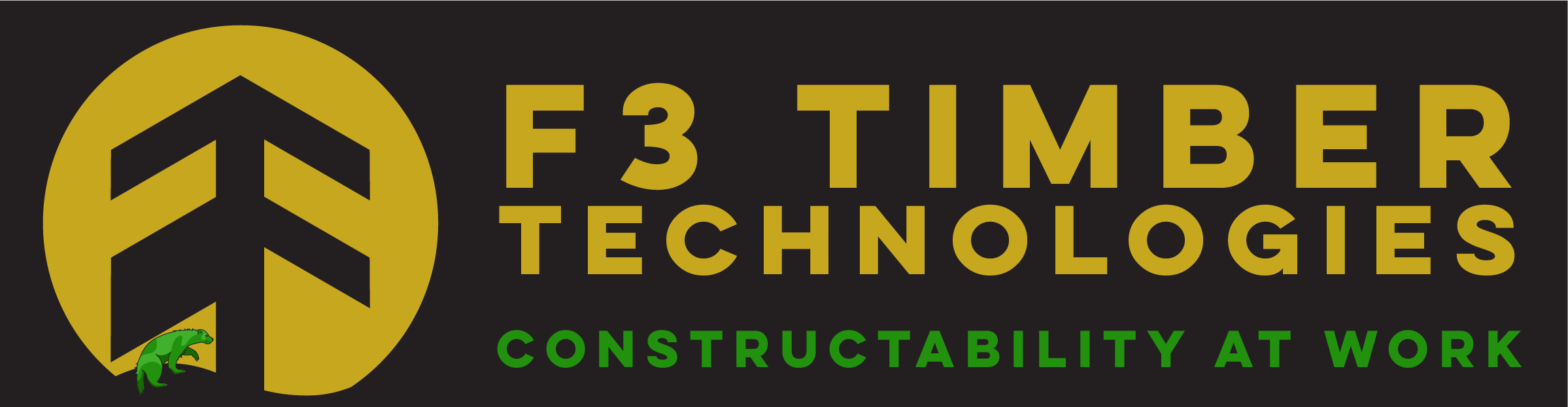

The friction part reduces screwing resistance by opening the hole slightly wider than the screw shank. It is usually combined with the half thread.

Friction Part Geometries

Partially Threaded

Partially threaded screws, also known as half thread, pull timber members or steel plates and timber together. For the design head pull-through and withdrawal of thread must be checked. Lateral loads as well as axial loads are efficient transferred.

The axial load capacity of the thread in comparison to the countersunk head is approx. 3:1. Using a washer head screw leads to a similar performance of the thread pull out and the head pull through capacity.

Compactor Tip

The compactor tip reduces the torque resistance by opening the hoe slightly bigger than the core diameter of the screw. This helps to prolong the battery life of the screwdriver for longer machine life and saves time during installation.

Compactor Tip.