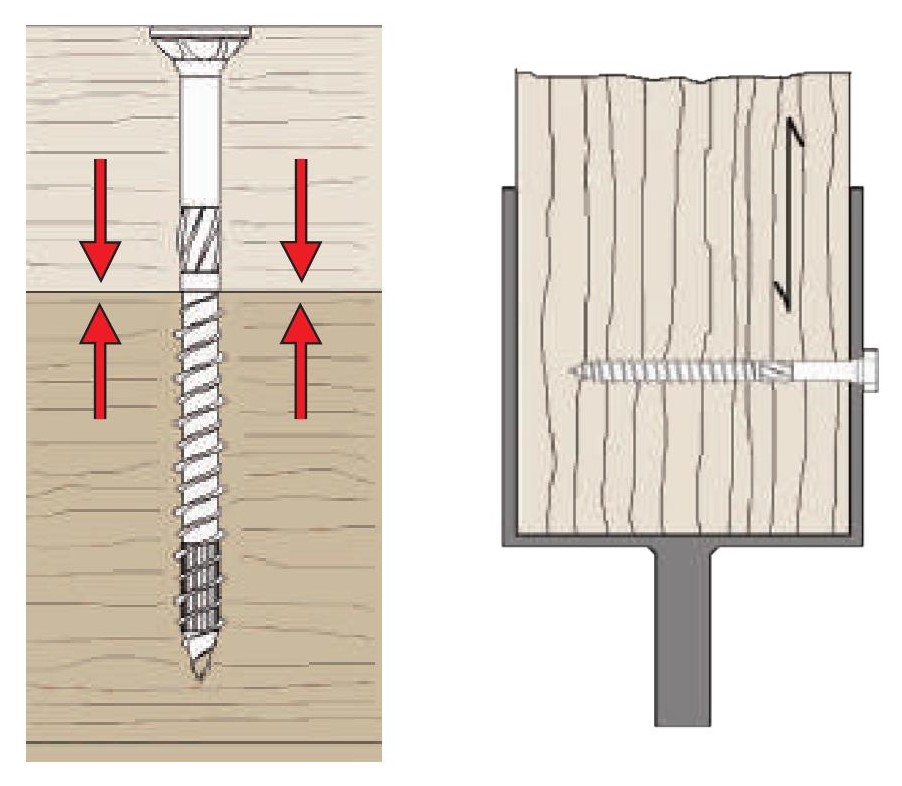

1 | Head geometry

- Better force transmission with hex drive possible – important for espacially hard wood used for the refurbishment of old buildings

- The commercially available time-consuming tool change

2 | Friction part and screw-in marker

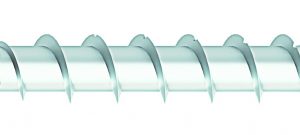

3 | Thread

Coarse thread:

- Quicker install

- Minimized blast effect

- Lower torque during fastening

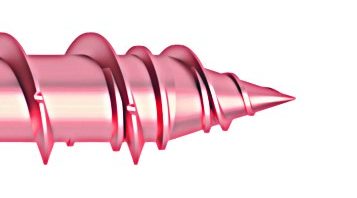

4 | Tip

Available sizes

Rapid® T-Con are available as 8 x 155 and 8 x 205 mm.

More

Additional information

| Head Geometry | Dual Head |

|---|---|

| Shank Geometry | Friction Part |

| Thread Geometry | Coarse Thread, Partially Threaded |

| Tip Geometry | Follower Tip |

Dual Head

Dual head allows for better force transmission with hex drive possible –

especially for high timber density and impact driver.

Wrench-openings:

screw Ø8mm = 12 mm,

screw Ø10mm = 15 mm,

screw Ø12mm = 17 mm.

The commercially available T-Drive saves a time-consuming tool-change.

T-Drive sizes:

screw Ø8mm = T-30,

screw Ø10mm = T-40,

screw Ø12mm = T-40.

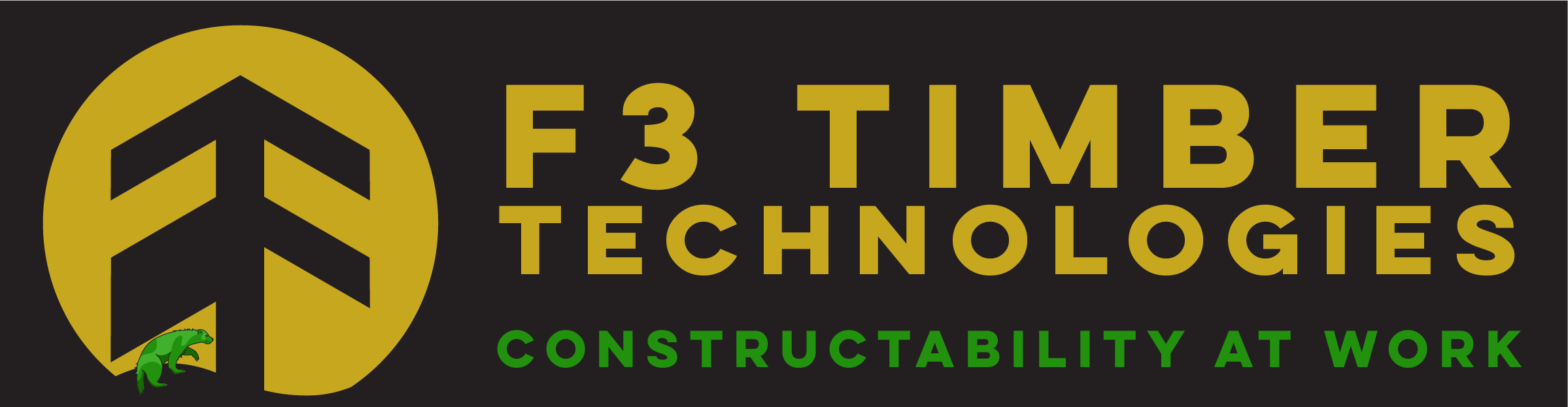

Friction Part

The friction part reduces screwing resistance by opening the hole slightly wider than the screw shank. It is usually combined with the half thread.

Friction Part Geometries

Coarse Thread

Coarse thread allows for up to one third faster install time due to a higher pitch of the thread.

Coarse Thread

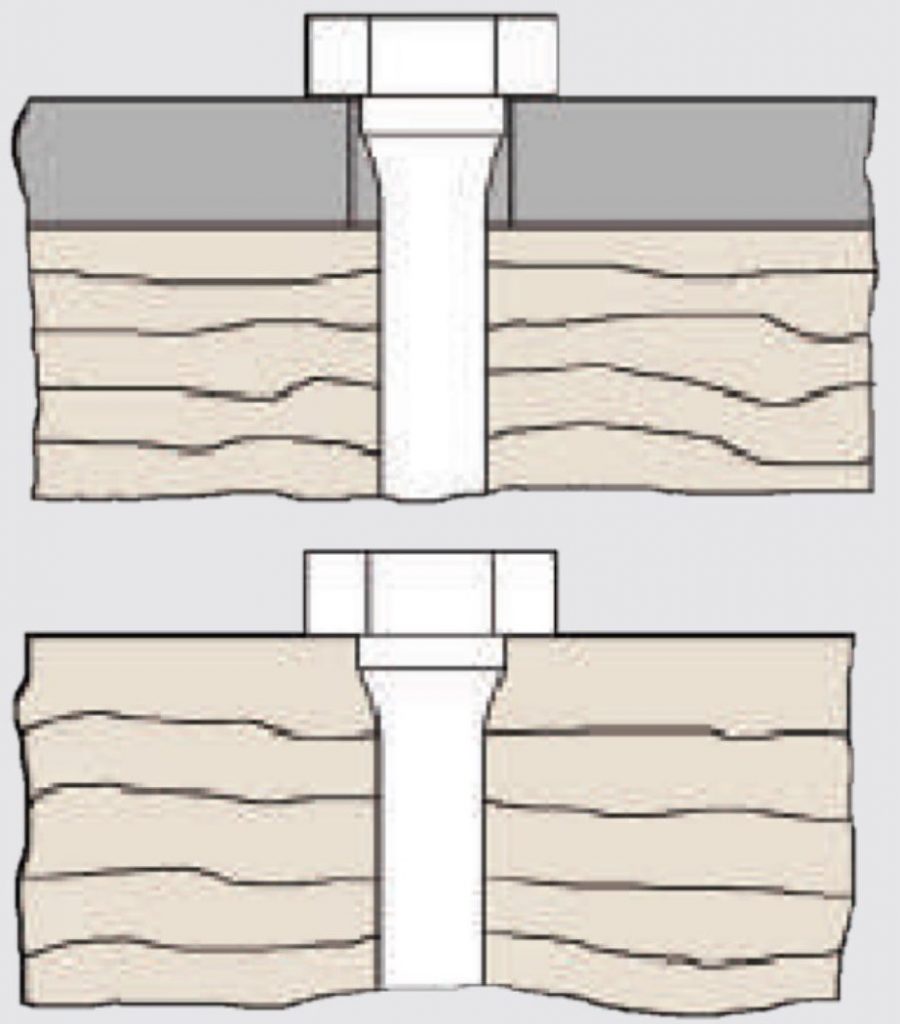

Partially Threaded

Partially threaded screws, also known as half thread, pull timber members or steel plates and timber together. For the design head pull-through and withdrawal of thread must be checked. Lateral loads as well as axial loads are efficient transferred.

The axial load capacity of the thread in comparison to the countersunk head is approx. 3:1. Using a washer head screw leads to a similar performance of the thread pull out and the head pull through capacity.

Follower Tip

Patented follower thread is an additional smaller thread at the very tip of the screw for a quick bite also at inclined positions.

Follower Tip