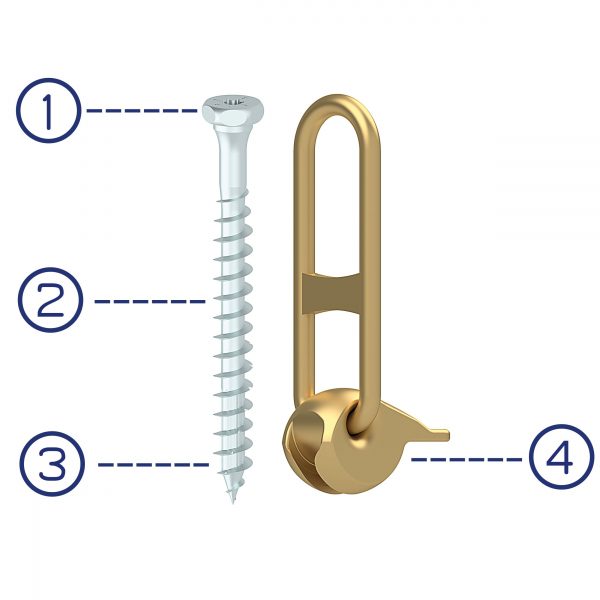

Description

1 | Head geometry

Dual head SW 17 (and T40) offers flexible screw connection. Reinforced lower head area with optimum fit for reliable power transmission.

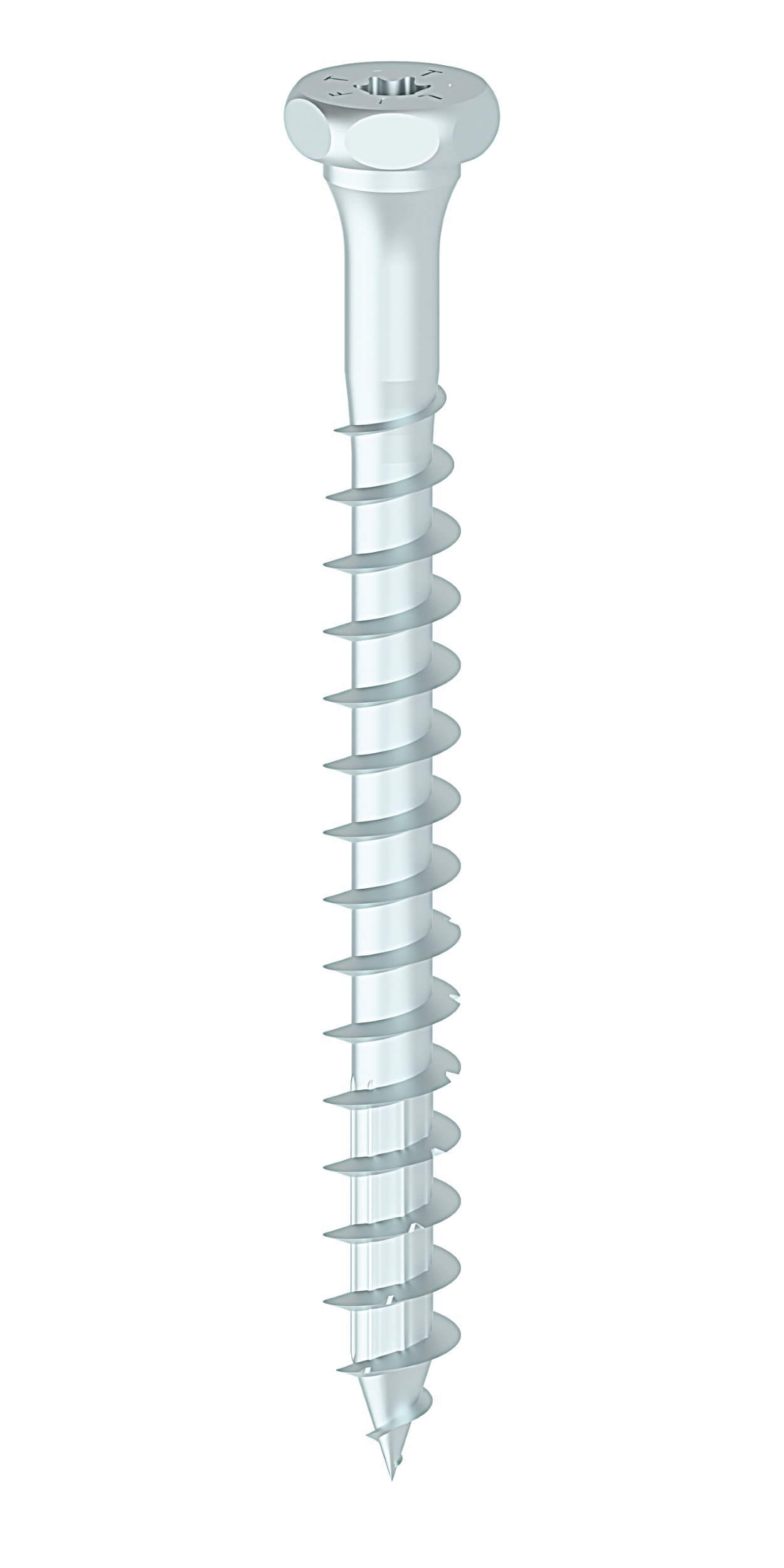

2 | Thread

Sharp rolled thread flanks for minimized blast effect, fast screwing-in and very high pull-out values

3 | Tip

Patented compactor tip:

- Quicker bite for reduced fastening torque

- Reduced split effect

- No pre-drilling required

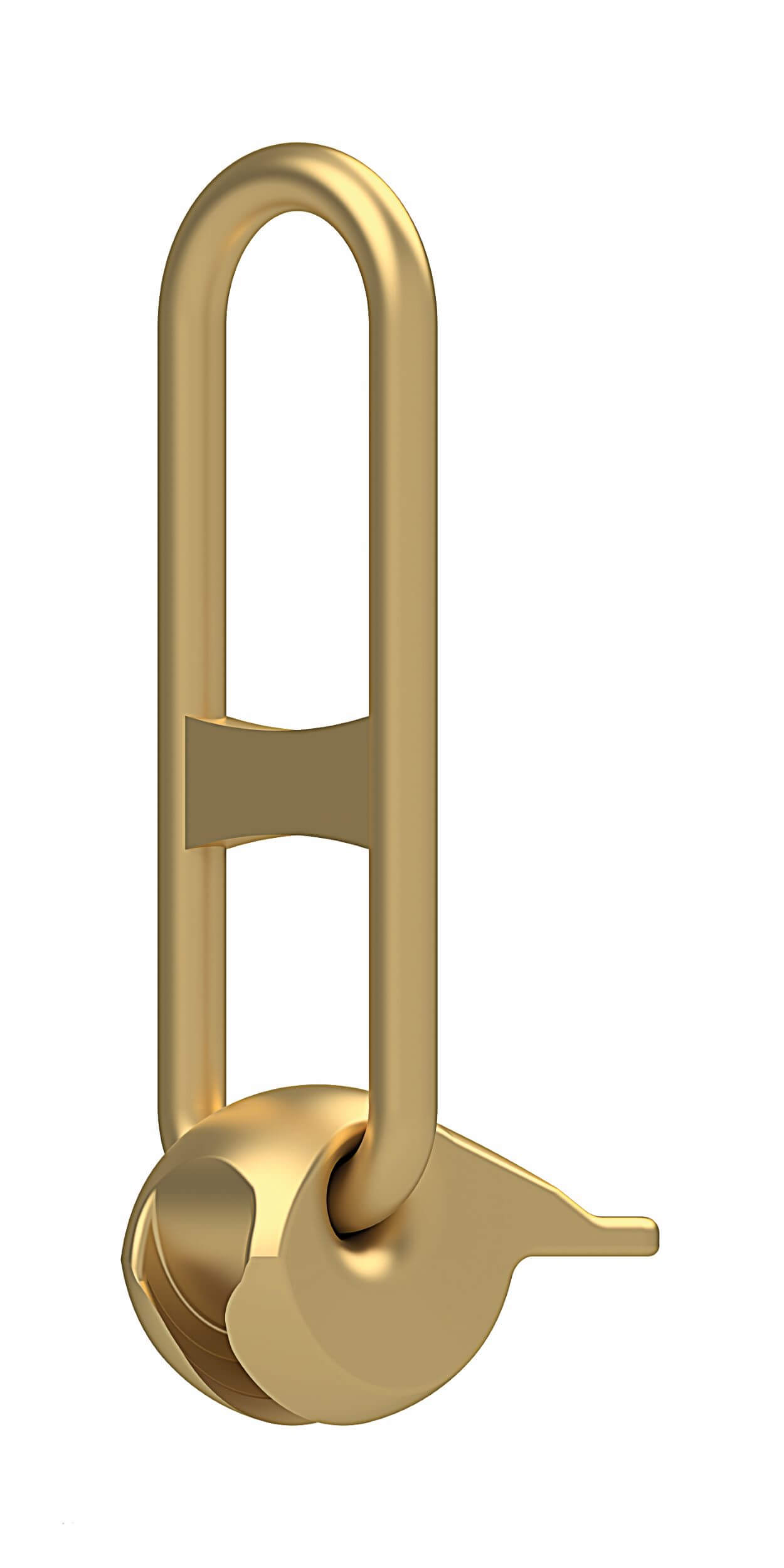

4 | T-Lift hoist

Reliable power transmission due to the optimum fit of the RAPID® T-Lift screw head with reinforced lower head in T-Lift hoist.

Available sizes

The RAPID T-Lift is available in:

12×60 mm*

12×80 mm*

12×120 mm

12×140 mm*

12×160 mm

12×180 mm*

12×220 mm*

NEW ETA approved prodcts on request:

12×300 mm*

12×380 mm*

16×180 mm**

16×240 mm**

16×280 mm**

16×320 mm**

16×400 mm**

16×600 mm**

*new diameter **with new 2.5t

Areas of application

- Use in building timber construction as lifting system for prefabricated roofs,

wall and ceiling elements, timber panel construction for the prefabricated house sector, solid wood panels such as laminated panels etc. - RAPID® T-Lift is suitable for plywood, solid timber, timber materials (OSB, LVL,

etc.) and softwood. In hardwood, we recommend using the screw with a pre-drilled pilot hole. - Suitable for axis loads (screw subjected to tension) and for transverse loads (screw subjected to shearing).

Application notes

- The lifting system corresponds to the load group up to 1.3 tonnes and is only tested in connections with Ø 12 mm screws according to ETA-12/0373 with a dual head.

- The weight of the components to be lifted must be known and must not exceed the calculated screw bearing force.

- Screws must not be screwed into drying cracks or similar defects.

- Screw-in angle in the timber: 0 – 90°

Saftey instructions

- For safety reasons, the screws must only be used once.

- The entire component must be lifted with at least two screws.

- Check the RAPID® T-Lift for damage before each use.

- At least 1x / year the lifting system has to be checked by an expert / safety officer of the user company. Apart from damage of all kinds, the degree of wear and tear in particular should be determined.

- Modifications and repairs, especially welds on the lifting system are not permitted!