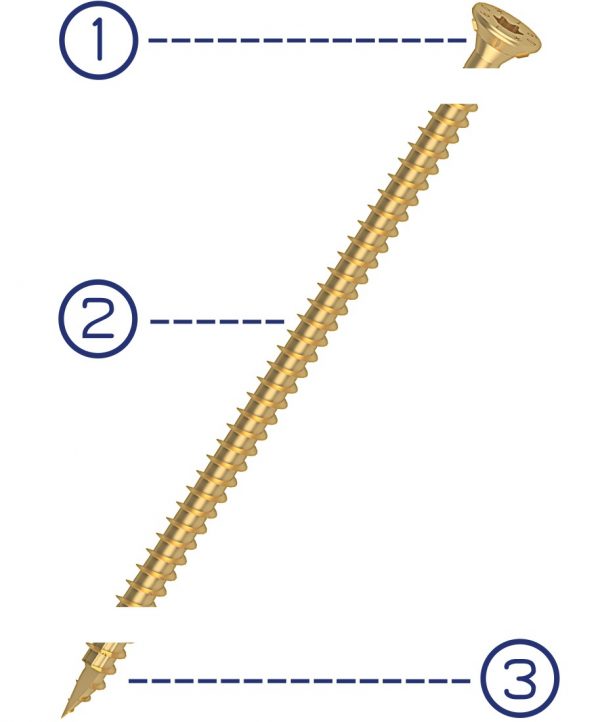

1 | Head geometry

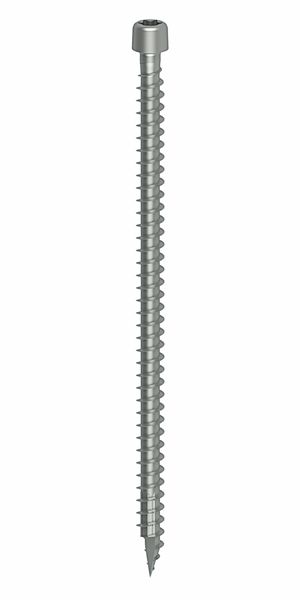

Cylinder head:

- Reduced split effect

- Deep countersinking of the head is possible

Countersunk head:

- Ideal for connecting steel components

2 | Thread

Full thread optimized for more efficient installation:

- Excellent pull-out values

- Excellent pressure values

- Maximum load-bearing capacity

3 | Tip

With patented half-tip, partially combined with compactor tip:

- Reduced edge distance

- Minimized blast effect

- Improved service life of the driving device thanks to 50 percent lower fastening torque

- No pre-drilling required

- Quick bite even when drilling in inclined position

Available sizes

RAPID® Fullthread are available in 8 x 120 to 12 x 1000 mm.

More

Additional information

| Head Geometry | Counter Sunk, Cylinder Head |

|---|---|

| Thread Geometry | Fully Threaded |

| Tip Geometry | Compactor Tip, Half Tip |

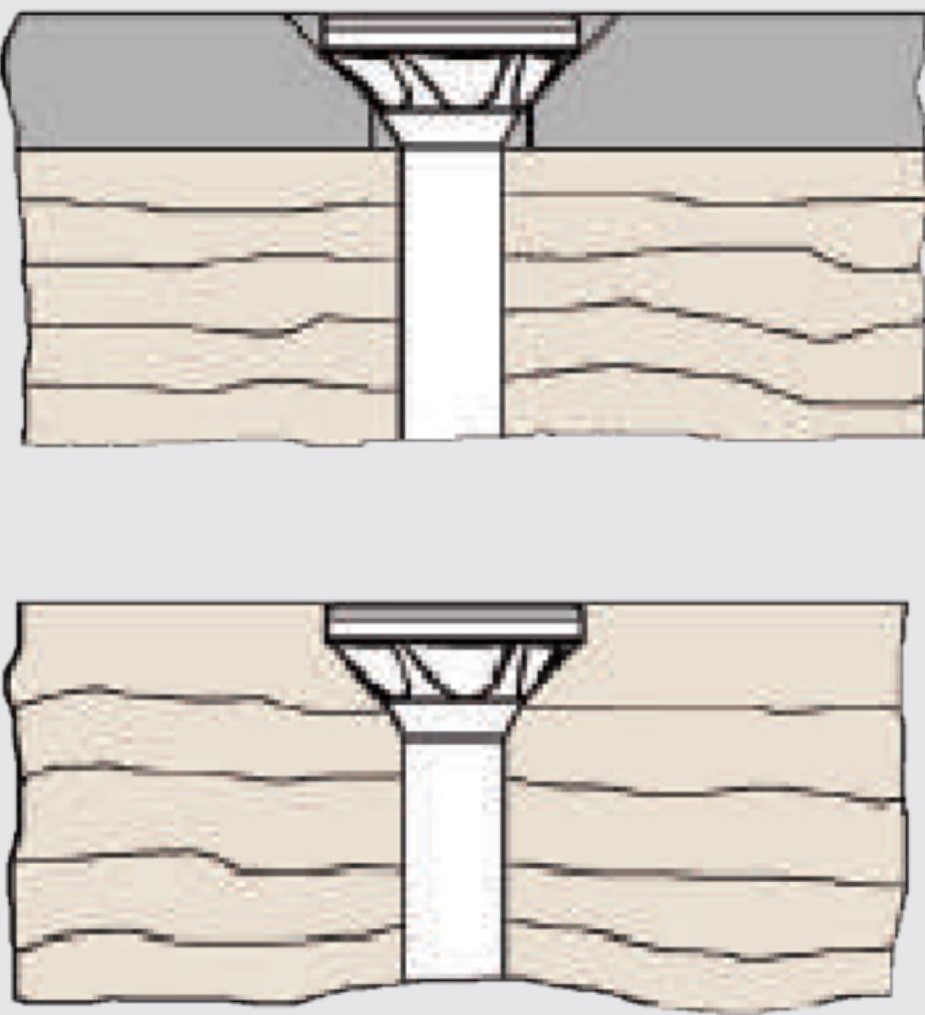

Counter Sunk

Countersunk heads are counter-sinkable in wood or even in prepared steel plates. The milling pockets reduce the fraying and splintering of the wood.

Cylinder head

Reduced blast effect Head is able to countersink deep into material Improved force transfer thanks to deeper drive

Fully Threaded

Fully threaded screws can withstand much higher forces acting along the screw axis because the load is held by the longer thread. The longer thread also increases shear capacities due to the rope effect.

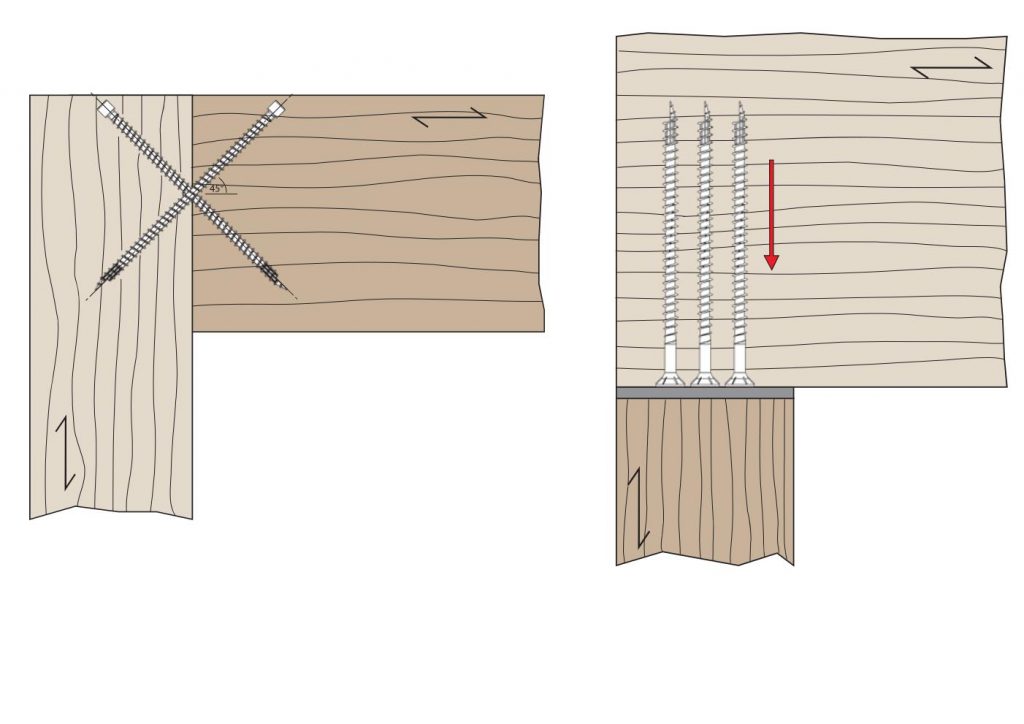

Steel to wood and also applications between timber members are common. RAPID® screws have very high withdrawal capacities through axial loading and can be used for installation angles from 90° (side grain) to 0°, driven into end grain. Many applications are possible, e.g. reinforcement in tension, shear and also in compression, cost efficient solutions with crosswise paired screws or even arranged under 45° connections.

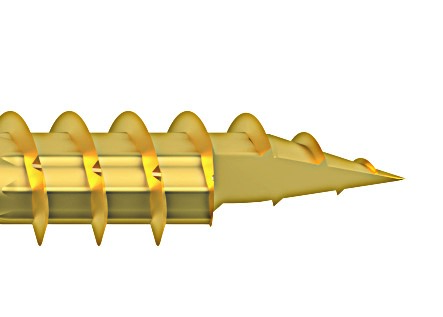

Compactor Tip

The compactor tip reduces the torque resistance by opening the hoe slightly bigger than the core diameter of the screw. This helps to prolong the battery life of the screwdriver for longer machine life and saves time during installation.

Compactor Tip.

Half Tip

The half tip ensures less deviation of the screw during install as well as reducing the splitting effect and therefore smaller edge and end distances can be achieved.

Half Tip.